AdZ's products

During our long and rich experience (since 1986), our numereous technical assistance (in more than 20 countries and more than 50 cold rolling complexes), most and main problems faced by Mill users are similar. Efficient technical solutions are often lacking.

Mill users’ difficulties not enough taken into consideration.

Basics are too frequently forgotten !!!

E.g. lubricant spraying is neglected.

→ These convinced us to design new concepts of Mill equipment:

Smart Spraying Ramp

SSR improves your quality, productivity, maintenance and safety:

- less roll marks, colored bands, aspect and magnetic properties more uniform

- 3 jets toward all the roll bites in the housing

- Flows adjusted one by one and along the ramp in static and in dynamic

- Temperature regulated across and along the strip

Particularly interesting for stainless and electrical strips - No rolling oil or emulsion turbulences (no nozzle, continu and regular jets)

- Enhances your productivity (easier strip, work rolls threading, less mainteance)

- No nozzle and stronger: mainteance simplifed

- More compact: head strip threading and work rolls introduction easier

- Compared with conventional ones, and stronger

- Improve the safety: half weight of conventional ones

- No modification needed in the mill and many others...

SSR exists in 4 versions: SSR10, SSR20, SSR30 & SSR40

For 20Hi, 18Hi (Z-Hi, X-Hi), 16Hi, 12Hi, 6Hi...; offline or online, single stand or in tandem...

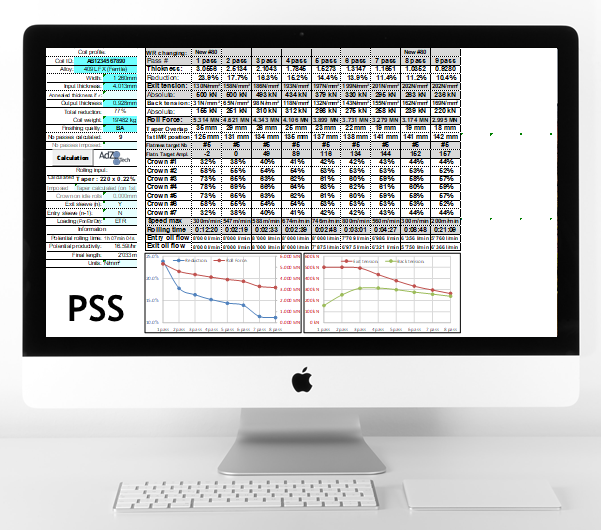

Pass Schedule Standardization

For quality assurance and standard production

The algorytms optimize the rolling parameters for each pass.

In the system, mathematic model and machine-learning modules are incorporated in order to best adjust rolling parameters:

- Reductions, tensions (entry & exit)

- Presets: rolling force, 1st intermediate rolls position, crowns, flow...

- Information: rolls changes, time / pass, total rolling time, max speed...

Can be used for any kind of rolling mill.

Our experts do on site commissioning and also tune parameters and train users.

Based on 40 years of data collection and modern machine learning, our digital solutions are designed to reduce risks, quality issues and to increase rolling mills efficiency. Our software outperform other industry standards and increase your ROI.

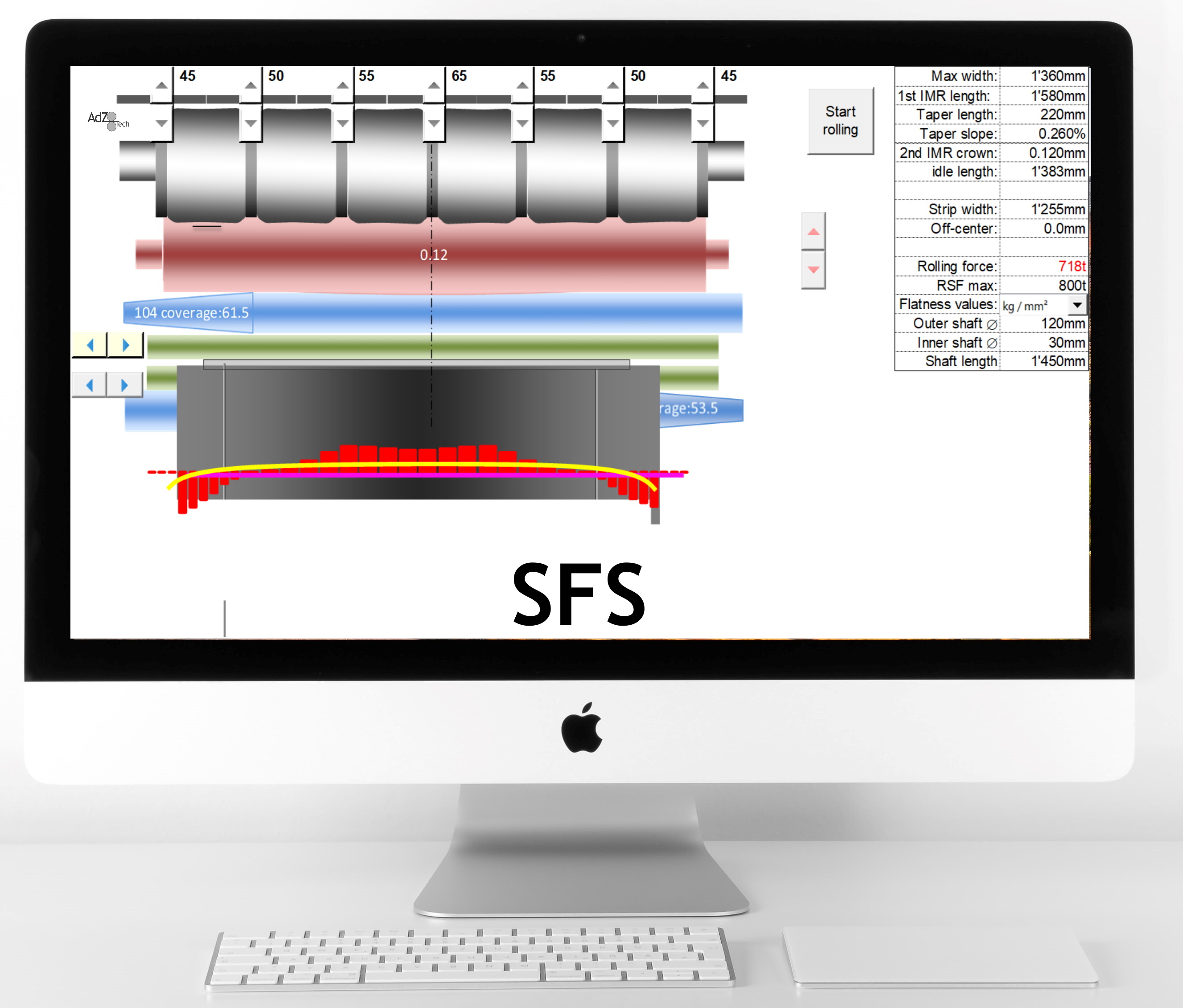

Software Flatness Simulation

Modern machine learning, our digital solutions are designed to reduce risks, quality issues and to increase rolling mills efficiency. Our software outperform other industry standards and increase your ROI.

Ideal tool:- To train Operators

- To predict the flatness for new maerials or new pass schedule

- To improve the rolls profile (like tapers on intermediate rolls, crown...)

Can be used for any kind of rolling mill.

SFS is compatible with ourPSS in order to predict the flatness results.

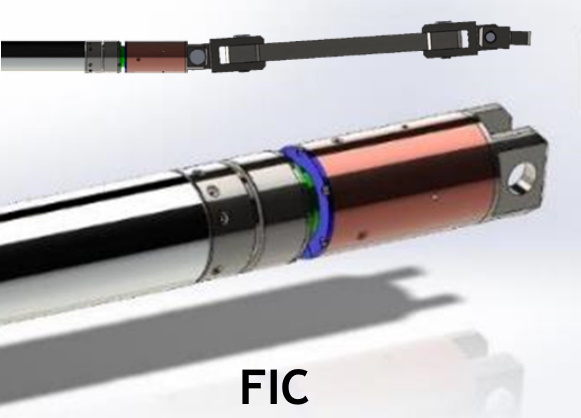

First Intermediate Connection

Finished the bearing boxes mounted onto the 1st intermediate rolls 😉

1 set of bearing boxes only by mill:

- No more disssembly/reassembly of bearings boxes between grinding and rolling

- Safer rolling: connection is controled during rolling

- Much stronger connection: hydraulically connected, continuously lubricated

- Faster and safer 1st IMR changing: no neeed for operator to go drive side for IMR reassembling: reconnection is done from OS

- Spare parts divided by 5, at least

- Very little modification in the mill

- Quick ROI.

FIC exists also for push-push system.

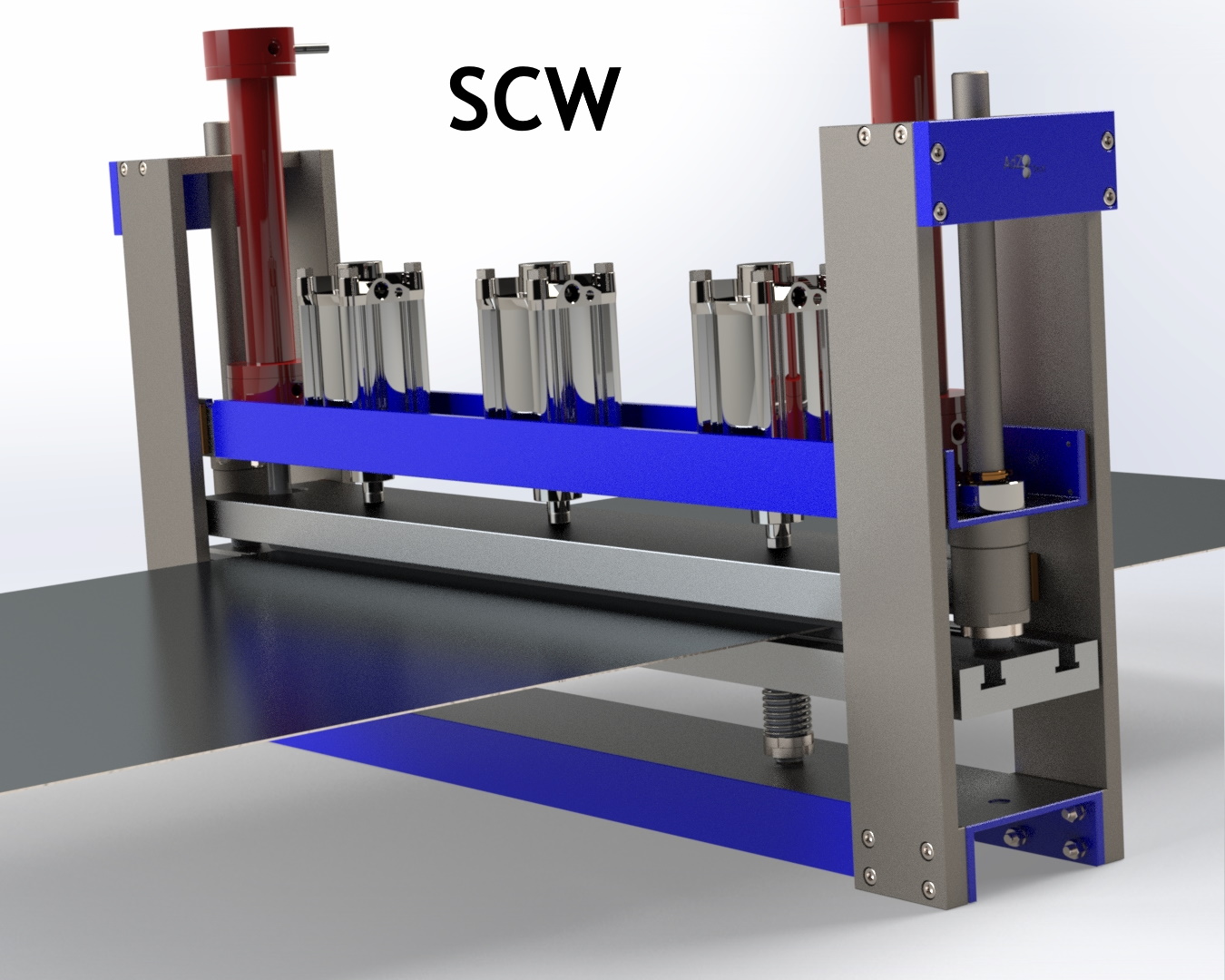

Smart Contact Wiper

Very effective wiping, SCW avoids coil telecoping, does not scratch the strip, evacuates rolling oil...

Ideal for thin gages:

- During rolling, rolling oil (or emulsion) is evacuated

- For thin and very long strips, the wipers wearing is limited

- Special wiper profile

- Very light pressure on the strip surface

- Quick and easy change of the wipers

Can be used for any kind of rolling mill.

SCW is the ideal wiping for thin strips (scratches and sudden sifting are avoid).

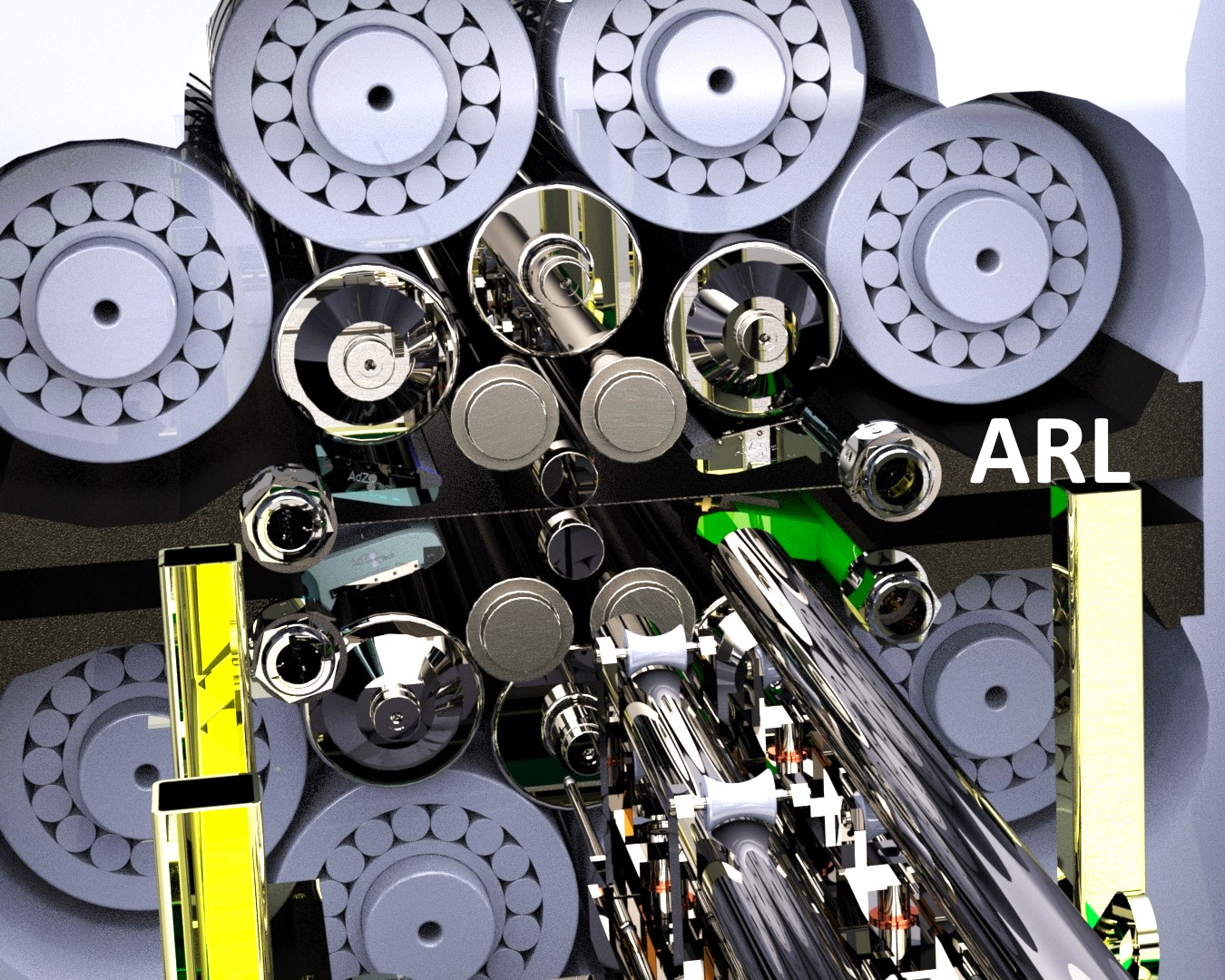

Automatic Rolls Loading

ARL eliminates risk for operator during changing rolls, work rolls, 1st and 2nd intermediate rolls, back-up assemblies😉

Only 1 operator to change the 20 rolls (or BURs):

- Rolls changed in safe conditions and conforming with the EC machinery directive

- ARL changes all the rolls (WRs, 1st IMRs, 2nd IMRs, BURs)

- Changes in very short times

- Productivity gains: +2.1% (according to your equipment specifications, like mill size...)

- Preventive maintenance included

- Automatic sequences

- Any movement, position controled: industry 4.0

- Little modifications in your mill

- Quick ROI.

ARL exists in 4 versions: for all of the 20 rolls, only for WRs and 1st IMRs, only for 2nd IMRs or only for BURs